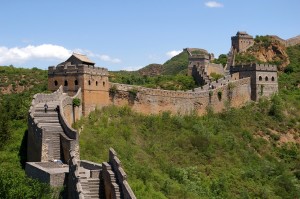

Magnesium-oxide based cements are some of the oldest building materials in the world, probably first used around the same time as gypsum. Unlike gypsum plasters though, magnesium oxide based cements can be very strong and durable. There are ancient examples, it was used as mortar by the Romans, in the Great Wall of China, to build Stupas in India, to protect wood structures like the Forbidden City and in 800 year old timber buildings in northern Europe.

About sixty years after Joseph Aspdin invented Portland cement in 1824, Stanislaus Sorel rediscovered magnesium based cements and patented Sorel cement. MOC has continued to be used for specialty applications like high temperature kiln linings, patching cement for airport runways and bridges, oil well mud, and hospital and institutional floors to name a few. From early in the 20th century Northwest Magnesite in Washington state was a world leading producer of MgO and also Thermax, a structural, fire and sound resistant building panel used in many iconic buildings. ASTM’s C02 committee wrote standards for MOC products in the 1950s and 60s. Around 1970 NWM and the CO2 committee both came to an end and the name Thermax was repurposed for polyisocyanurate insulation.

The Japanese used sorel cement for their fortifications in Manchuria circa 1918. When Mao re-captured Manchuria they gained the Japanese research and made MgO cements part of the Great Leap Forwards around 1970. Modern uses for MOC have been developed in China since then including the fiber-matt reinforced wall boards becoming popular now. For the Beijing Olympics mago boards were used extensively as the premier material to make the games more environmentally sustainable. Taipei 101, the world’s tallest Platinum LEED building, uses it extensively on walls and ceilings, inside and out, for decoration and fire proofing. In Europe it is replacing OSB as the sheathing of choice due to its strength, durability, and ease of use.