2014 was a very good year for MagO, and we would like to extend our thanks to all of you for your support in making things happen. We have completed more projects; we have more architects specifying MagO and we have learned more about this remarkable product.

Most importantly our roster of staff has grown; Mark Herrmann is now managing the commercial side of MagO leaving me more time for more outreach, there is still an awful lot of ground to cover spreading the gospel of MgO. Maggy Tong is keeping track of logistics and administrative stuff while helping out, as we all do with sales. Af Khan is still the guy to call when you want a lunch and learn, 45 scintillating minutes of power point which provides a decent understanding of MgO boards and a great lunch on us. Af has arranged 35 of these over the last 18 months or so.

Call us for yours.

We are ontrack for making our own board in Canada with all the raw materials already secured from local sources.

Research will take place at UBC with Prof. Greg Dipple for carbon footprint analysis, at BCIT Building Science Center of Excellence with Fitsum Takiru for interior air quality and moisture modulation, and at NAIT for developing new formulae using state of the art cellulose fibers.

We have a new shareholder and angel investor Ad Hanna. Ad trained as a construction engineer in France and is looking to divest his master franchise janitor business and get back into construction full time with MagO. Welcome Ad and thank you.

First the projects – nothing speaks louder than photos of successful installations.

Coast Plaza Resort main entrance showing MagO silhouette panels,

** Coast Plaza Resort Calgary.

————————————————————

FNDA Architects in North Vancouver experimented with a few thicknesses of MagO and settled on 8mm for most of this job providing a face lift to the Coast Plaza Resort in NE Calgary.

For this project MagO has been used for a variety of exterior decorative elements. Most of this project used 8mm boards that were routed by hand and finished on-site although the soffit panels are 6mm supported in a T-Bar frame. 6mm would weigh .65 lb / sq ft and, like all MagO panels, is non combustible. Oakwood Enterprises profiled the sheets using a hand router. They also designed and built the support structure and installed and finished the panels.

After a severe windstorm in September a few panels cracked in proximity to the unsupported vertical edges. We have learned from this that all edges for thinner boards at least, need to be supported and secured with fasteners and best practices may include a backer of some sort, a laminated film perhaps for thinner panels. Time will tell how well these silhouette panels take the abuse of weather and impact but so far so good.

Lessons learned.

Exterior panels should be supported on all edges and fastened 12 inch on center.

Fasteners must have a barrier coat such as Grabbergard by Grabber. Hot dipped galvanizing or zinc coatings are not suitable for exterior or wet area use due to the reaction between water and magnesium chloride.

Fasteners should be countersunk and the holes filled with Rapid Set One Pass now available from MagO.

Exterior panels can be field coated but it is much better to have them factory coated. Cloverdale Paint Weather One is our default factory applied coating which can provide a 25 year coating warranty as applied by Fisher Coatings.

Sherwin Williams Loxon primer with suitable top coats are still our recommendation for field coating.

New Stuff:

We are now stocking Rapid Set One Pass in 25 lb bags. This is our recommended filler for joints and repairs.

Rapid Set One Pass

We will soon be providing Grabber screws with Grabbergard coating for most applications. Grabbergard has a baked on ceramic barrier coat over an anti corrosion film over zinc. Grabbergard

On a custom order basis we provide Stockton Products extruded aluminum trim for 8 mm boards. visit www.stocktonproducts.com and look for fiber cement board moldings.

Buildex, MagO has a larger booth for this year’s show, booth 1413 and will also be at IBS in Vegas Jan 20th to 23rd in booth S1636, hope to see you all at one or both of these shows.

MagO Cladding is now available in custom sized panels for each project. Working with George Liu at Absolute Space Engineering who provides a survey of elevations allowing MagO to create shop drawings for panels that will be custom machined and labeled for almost cut free installation on site.

MagO Cladding is availble in either standard sized 2×8 and 2×10 panels with a shiplap edge on all edges or in custom sized panels made for each job. The costs for custom or standard panels is the same.

MagO Cladding is available through Mitten Exteriors in Canada and Evergreen Building Products in Washington and Alaska.

MOCA

Just before the end of the year the first invitations and draft charter for MOCA the Magnesium Oxide Cement Association, were sent out. MOCA will be the vehicle to bring all the parties interested in MgO cements together in order to develop baseline or generic quality and strength properties for all boards sold in Canada. MOCA will also help drive awareness and provide information on MgO cement products. The goal is to have MgO in the National Building Code by way of CCMC. Please let us know if you would like to join us.

Banff to make a presentation (

Banff to make a presentation ( The power of the water to pretzel steel picnic tables and rip 3 ft concrete foundations out of the ground is a clear indication what we can expect to see if the pipelines are ever built across BC, bituminized valleys and streams does not sound like a very good outcome for this shortsighted project.

The power of the water to pretzel steel picnic tables and rip 3 ft concrete foundations out of the ground is a clear indication what we can expect to see if the pipelines are ever built across BC, bituminized valleys and streams does not sound like a very good outcome for this shortsighted project.

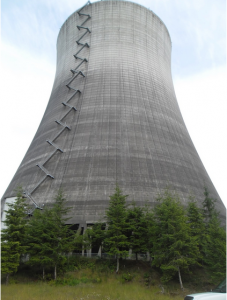

he Pitt Meadows RCMP station / Community Center building on Harris Rd. Ratio Architecture, who used to be known as TRB Architects have been an early adopter of MagO specifying us in at least 2 projects so far – one of the above noted addition to the community center and the other an industrial use for Township of Langley Water Treatment facility to be built this summer.

he Pitt Meadows RCMP station / Community Center building on Harris Rd. Ratio Architecture, who used to be known as TRB Architects have been an early adopter of MagO specifying us in at least 2 projects so far – one of the above noted addition to the community center and the other an industrial use for Township of Langley Water Treatment facility to be built this summer.